- Mini Cnc 3018 Software Download

- Sainsmart Cnc 3018 Software Download

- Cnc 3018 Pro M Software Download

- Cnc 3018 Pro Software Download Usg

- Cnc 3018 Pro Software Download Mac

Downoad files:

With a 1.8-inch effective engraving depth, the 3018 mini CNC machine is capable of cutting all types of plastics, soft aluminum, woods, acrylics, PVCs, and PCBs, and a wide range of other materials.

1.Overview

- 🛠️【MYSWEETY CNC 3018-PRO】- CNC 3018-PRO is an upgraded version of 3018. Control software: GRBL; Working area: 30x18x4.5cm; Spindle: 775 spindle motor (12-36V) 24V:10000r / min. Supported System: Windows XP / Win 7 / Win 8 / Win 10. 🛠️【Offline Controller】- The offline controller is 1G Capacity.

- Join 9,170,000 engineers with over 4,770,000 free CAD files Join the Community. The CAD files and renderings posted to this website are created, uploaded and managed by third-party community members. This content and associated text is in no way sponsored by or affiliated with any company, organization, or real-world good that it may purport to.

- Join 8,960,000 engineers with over 4,690,000 free CAD files Join the Community. The CAD files and renderings posted to this website are created, uploaded and managed by third-party community members. This content and associated text is in no way sponsored by or affiliated with any company, organization, or real-world good that it may purport to.

- CNC Design Limited Developer tools Utilities This is a configuration tool for setting up the popular GRBL CNC Machine motion controller using Windows 10.

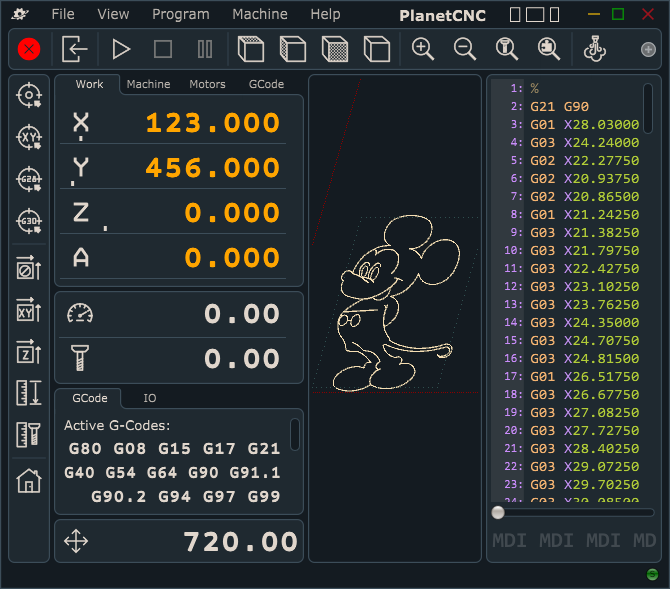

Candle is an open source software suitable for CNC machine tool processing. It supports G code file processing and visual display.

2.Install the driver

For the first time use, please connect the device to the computer via USB cable, and click the CH340-Driver.exe file in the driver folder to install the driver. Under normal circumstances, the Win10 system will automatically identify and install the driver. For Win7 and Win8 systems, please install it manually.

3.Set the port

After installing the driver, open the device manager of the computer and click on the port option to see the content inside the red box on the screen shown in the figure below (the port information is in brackets).

Remember the port information queried above, switch to the Candle software interface and click the “Settings” option in the upper left corner. Selecting the setting will bring up the interface. Under “Connection”, select the port name you queried, select the baud rate 115200, and then click below The icon “Finish” ends the setting

4.Connection is complete

After setting the port and baud rate, click Finish. The status bar at the top right of the Candle interface will show Idle, and at the same time, the console at the bottom right will display the information shown below, indicating that the connection has been successfully established.

5.Processing documents

The “File” option at the top, click “New” to create a G code in the command bar at the bottom of the interface, and click “Open” to select a G code file that has been made, and then you can import the file. After importing, the middle of the interface will display a visual graph composed of tool paths (the position of the pen-shaped graph in the graph is the current tool position). In the visualization window, hold down the left mouse button to move to rotate the graph, and hold down the right button to move. Graphics, scrolling the middle wheel can zoom in and out of the graphics. At the same time, the content of the G code will be displayed in the lower command bar. During processing, the machine will run one by one according to the G code commands.

Mini Cnc 3018 Software Download

6.Set the working coordinate origin

Before running the G code program, you need to find the position of the engraving figure relative to the overall engraving plate. There is a three-axis coordinate system in the visual graphics. The origin of the three-axis coordinate system is the tool setting point of the actual processing graphic. You can move the tool to determine the position of the engraving graphic relative to the overall engraving plate based on the position of this origin. The engraving figure in the figure below is taken as an example. After the selected tool position is started, the X, Y, and Z axes are reset to

zero (the axis is reset to zero, and the Z axis is reset to zero buttons). Before returning to zero, make sure

that the tool approaches the distance of one sheet of paper for engraving, and then return the X, Y, and Z axes to zero (please use a flat-bottom sharp knife when engraving, and use a cylindrical milling cutter when machining planes, slots, and holes) The effect is that the sculpted figure will be carved with the blade tip as the origin.

Writing G codes for manufacturing components from your design can be very time-consuming and may consume a lot of resources from your workforce. CNC router software is basically designed to generate G codes based on your design. You can also expect design optimization for particular manufacturing technique from the software. Following is the list of few of the best picked CNC router software.

Related:

Sainsmart Cnc 3018 Software Download

EnRoute

EnRoute is a CAD/CAM sign making and digital finishing software solution. The software is paid software with the basic version offering features for design, toolpathing, 3D surfacing, Nesting, and production. The long list of features include a complete set of 2D CAD and editing tools, interlocking components creator, 3D relief surface cutting, carve into the surface, true shape nesting with 3 nesting engines, nest near obstructions, and save and reuse toolpaths for fast workflow.

CNC Machine

ConstruCAM 3D works with only one unitary data file- click and go. The software provides an interface for most of the standard formats, thus data can be adopted from AutoCad, coreIDRAW, and ADOBE Illustrator. The software has a long list of features including construction aids, editing, layer technique, tool administration, lines, cubic splines and complex pre-defined elements. The software has integrated “Relief” module to convert 2D or .stl file into 3D file.

Mozaik CNC

The CNC router software from Mozaik will take you from design to fully developed machine ready G-code with ease. Few of the features from the long list of this software offers are huge pre-defined parts giving you almost all the parts ready for drag-and-drop, intelligent joinery, intelligent algorithms to get optimized nesting, and the ability to control localized nesting. The software is available with a price tag.

LinuxCNC

LinuxCNC is the software designed specifically for Linux platform for controlling CNC operations. The software can be used to drive milling machines, lathes, 3d printers, and laser and plasma cutters. The software accepts G-code as input and drives CNC Machine in response. You can select your preferred GUI from a variety of GUIs. The software supports rigid tapping, cutter compensation, and many other advanced control features. This software is an open source CNC controller.

CAMotics for Mac

Cnc 3018 Pro M Software Download

Camotics is the CNC router software basically designed for Mac platform users. Camotics is open source software which simulates 3 axis CNC milling or engraving. Being able to simulate is the critical part of creating CNC tool-paths, and programming without simulating is just like cutting without taking measurements. With Camotics you can preview your cutting operation before you actually start the operation. This allows you to improve your design or optimize manufacturing process before the actual manufacturing begins.

Easy CNC for Windows

Easy CNC is the CNC router software basically designed for Windows platform users. Few of the features that this software offer includes full implementation in C++, compiling and loading with Arduino IDE, Doxygen documentation, G-code interpreter, High modularity with object oriented programming, and firmware support for RAMPS 14.

Cnc 3018 Pro Software Download Usg

Best CNC Router Software – GRZ CNC Software

Cnc 3018 Pro Software Download Mac

GRZ CNC Software is the most popular software in the CNC router software category. The goal of development of this software is getting direct G codes ready for machining from your designs. Meshcam supports almost all the 3D drawing formats, plus it supports reading from a .dwg format to feature designs from drawings. The software also has an automatic toolpath wizard to get you machined workpiece without implementing time and knowledge for the manufacturing process.

How to install CNC Router Software?

Many of the CNC router software listed above offer a setup file, allowing an easy installation of the software. Few of the software in this category are portable, giving you access from anywhere with just one requirement of bootable USB device. CNC router software is basically designed for getting simulation before running actual machining process to get an idea of the performance and let you optimize the process before actually starting the process.

While some software in this category offers free service for the basic need of getting simulation, the number of features gets limited for the free version. If you are looking for fully featured software with advanced features like automatic G-code generator and optimization, the paid ones are for you. Each software offering some unique feature over others, it’s the question of personal preferences for selecting one of the best software listed here.